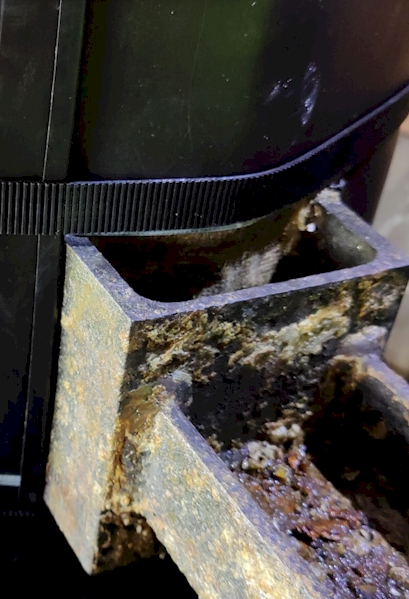

HCL’s Pile Wrap Protection System was selected to be used to rehabilitate over 300 Piles on a Fishing Jetty. The Piles were combination of octagonal Frodingham Type #4, #5 and 600mm Round. This Jetty was somewhat unique in that previous strengthening works had already been undertaken which had encased the piles from roughly low water to the seabed but left the top portion of the piles in a bare state. As these Piles were showing signs of corrosion the requirement was to protect the bare steel between the soffit and the strengthening encasement. This band was different on all piles when surveyed so a flexible system was needed in order to account for this.

HCL supplied our Pile Wrap system with variable overlapping jackets so that the different protective heights between soffit and casing could be catered for with ease. The PWS was pre-marked with white lines indicating where bands should be placed after the overlaps had been taken care of. Some of the piles were rakers or battered and these were trimmed to suit on site. Paste at roughly 0.5kg/sqm was applied followed by 55% overlap of Marine Piling Tape. The soffit was treated to a single overlapping wrap of PVC/Bitumen tape to ensure a good seal and the whole was protected by a 2mm HDPE jackets held securely in place with 19mm POM Hybrid Smart Band System. The jackets featured an edge seal.

As the anode brackets were welded on at random places there was no way without a very expensive pre-fitting survey of modifying the jackets in the factory prior to delivery. This is where the HCL PWS comes into its own with the ability to easily modify the jackets on site to accommodate such items. In this case a measurement was taken from the bottom encasement to the bracket and that was transferred to the bottom jacket. As the bracket size was already known this was then made into a cut-out on the jacket on the underlapping side so that when the jacket was offered up the edge seal was against the bracket and the cut out passed under creating the tightest fit possible. A set of drawings were also created to help the installer understand this process prior to carrying out the work from a floating pontoon.

16.05.2023

16.05.2023

09.03.2023

09.03.2023

13.10.2022

13.10.2022

08.09.2022

08.09.2022

12.05.2022

12.05.2022

24.03.2022

24.03.2022

25.06.2021

25.06.2021

04.11.2020

04.11.2020

06.10.2020

06.10.2020

10.03.2020

10.03.2020

09.07.2019

09.07.2019

Main office:

Clamping house

1st avenue westfield industrial estate

Radstock, bath, somerest

Ba3 4bs

United kingdom

Main office:

20220 Hempstead Road,

Suite 25

Houston, Texas, 77065

USA